The circular economy is becoming more and more important as a way to build sustainability. As virgin resources are depleted, costs are increasing, and widespread pollution continues to be a major problem. The way to achieve a long term sustainable economic future is by creating closed loop systems that require minimal new resource inputs and produce as little waste as possible.

The primary issue with discussing the circular economy and the types of business models that make it up, however, is identifying all the pieces of a circular approach and where your business or you as a consumer fits into the puzzle. Where is your place in this closed loop?

What is the circular economy?

As we’ve explained in other articles, the circular economy is a fundamentally different way of doing business and looking at production that is a huge departure from how we have looked at it over the past two centuries.

Materials travel in one direction until they are thrown out, and value comes only from producing and selling as many products as possible. The primary problem with this approach is that natural resources are thrown out while they still retain a large amount of residual value. Companies then need to purchase more resources more often, resources become scarcer, and highly valuable existing resources waste away in landfills.

A circular approach means finding creative and profitable ways to feed production processes, manage byproducts, procure resources, and design products in a way that reduces waste, lessens dependence on new resources, and extracts the most value from goods.

We’ve mentioned closed loop systems a few times now, and you might be asking yourself, what is a closed loop model or economic system?

The infinite loop

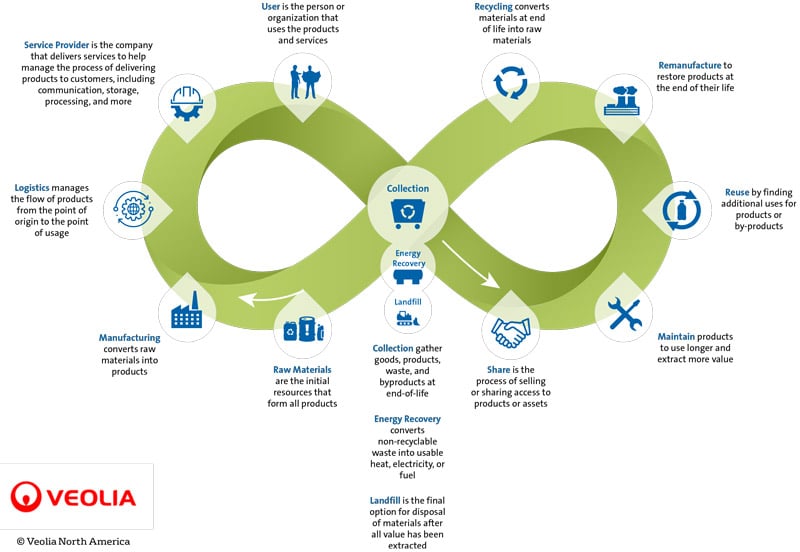

When we talk about closed loop systems in the circular economy, we’re referring to the infinite loop (illustrated above). Although you may notice that this graphic is not a completely closed loop, as virgin raw materials are being added on the left hand side and there’s a landfill icon center, the main idea of the circular economy is to get as close as possible to a closed loop.

On the left side of the graphic, virgin raw materials and resources are combined with recycled goods and materials from the right side to serve as feedstock in manufacturing and industrial processes. In circular economy models, finished products are delivered to businesses and consumers who then sell, share, or otherwise find innovative ways to lengthen the life of the product and gain as much value as possible from it.

What really sets circular models apart from traditional modes of production and consumption is that products are designed and built to last longer and to be more easily recycled, more effort is put into maintaining them, and reusing and recycling captures any residual value. On the manufacturing side, efforts are taken to utilize byproducts as energy and feedstock for other manufacturing operations.

What do each of the icons in this loop mean and how do they fit into the circular economy?

Raw materials

Like we mentioned, virgin raw materials are still a critical element of our current economy and of the emerging circular economy. The reasons for that are that 100% of resources and energy used in production can’t always be recycled or recovered, not all byproducts can be put to further use, and, on a basic level, populations grow, which then require more than the existing pool of resources and energy.

When moving towards a more sustainable, circular model, businesses don’t have to or can’t always survive using solely recovered materials. Like we said, the idea is to take steps in that direction and move as close as possible to a closed loop.

Manufacturing

When it comes to manufacturing, becoming more circular comes down to finding more sustainable ways to acquire feedstock, as well as finding profitable, environmentally friendlier ways to deal with byproducts. That means things like diverting heat from incineration to use in concrete or energy production processes, recycling rubber from old tires to replace new rubber, and converting food waste into renewable gas energy.

A report from the Ellen MacArthur Foundation estimates that the full value of circular opportunities, globally, could be as much as US $700 billion each year in materials savings. By reducing or eliminating waste through the reuse of materials, businesses not only save on the cost of waste disposal, but also gain by selling or turning that waste into a product that can be used again.

Logistics

Once created, products have to move from the manufacturer to market. Additionally, byproducts from one production process must be transported to be used as feedstock in another. All of this takes vehicles and fuel, most often carbon based fossil fuels, as well as storage. A more circular logistical approach involves efficient control of material streams: accurate monitoring, traceability, and novel logistics solutions.

By adopting more efficient routing and vehicles that use less fuel, organizations can drastically cut resource inputs, reduce pollution, and lower their costs. When it comes to storing goods, becoming more circular means using technology for things like seeing where heating and cooling energy is lost, ensuring proper insulation, and using energy efficient lighting. Additionally, by removing unnecessary aisle space and maintaining the correct inventory to sales ratio, you can cut down on the amount of warehousing space needed.

The idea is to reduce the amount of energy and resources required for this stage of the production and delivery process.

Service provider

Once finished products are created and delivered to distributors or other businesses, the next step is how to actually move those goods into the hands of consumers. In traditional, unsustainable business models, goods are created, sold to the customer, forgotten about by the manufacturer and distributor, used, and then thrown away by the end user.

An alternative method to this traditional approach is a Product as Service business model. Examples of this model include car rental companies and print shops. Instead of selling the product, the company retains its ownership, and the customer pays the company to use the product for a defined period of time. With this model the owner manages the product while it’s used and is in charge of maintenance, reuse, remanufacture and recycling the product.

In other words, products get more use and a greater amount of value is extracted from them and the resources that went into them.

User

The next step is where consumers like you have a massive role to play in developing a circular economy. Although some products cannot be recycled or reused after their first use per their designed intent, many can. In most cases, it is up to the consumer to purchase the longer lasting product. Choose companies with more sustainable practices and recycle products whenever possible.

- Recycling is key – Recycling is one of the largest roles consumers can play. From batteries to plastic bottles to food, the things we often throw away still have a lot of value to offer. Ensuring that recyclable items are disposed of in a way that allows the resources within them to be used again is a responsibility for each of us.

- Buying products that last – Another piece of the circular economy that falls on consumers is understanding what they’re buying. Purchasing higher end products that last longer but are more expensive may actually be more cost effective in the long run. Plus, buying higher quality products less often than lower quality, cheap products helps us conserve limited resources and put existing resources to better use.

Recyclables / reusables entering their second life

Share

The sharing business model has already seen huge growth in popularity. The idea is that as your car or vacation house sits unused, there’s more value that could be extracted from it. Sharing platforms connect underutilized goods with people who are willing to pay for them.

Examples include ride sharing services like Uber or Lyft and short term accommodation rentals like Airbnb. The primary difference between this model and leasing models is that the typical period of usage for sharing is usually much shorter, and the number of customers using the product or asset is much greater

Maintain

A huge component of developing the circular economy is maintaining and repairing existing products rather than discarding them at the first sign of trouble. By helping products last as long as possible, we avoid the need to create new products, extract new resources, and use more energy for the entire process. Examples include repairing items like phones, computers, shoes, and even clothing when you have issues with them, instead of throwing them away and buying new ones.

Reuse

The concept behind reusing is the fact that just because one person is done with particular goods doesn’t mean that another person wouldn’t still use them. Additionally, just because a product fulfilled its original purpose doesn’t stop it from serving another purpose. Reuse keeps goods and products as is and avoids discarding them until more value has been extracted from them. By reusing, we cut down on the demand for new products and the resources and energy necessary to create them.

Recycle

Similar to reuse, recycling takes advantage of the residual value that the resources within goods and products still have to offer. However, whereas with reuse products are kept as is, with recycling products are broken down into their elements, which are then used as resources to create different products. Whether reusing the metal from cars, the rubber from tires, or the glass from bottles, recycling drastically cuts down on the raw materials and energy that go into extracting and manufacturing virgin resources.

Remanufacturing

Similar to maintaining and repairing products, remanufacturing falls under the product life extension business model. The goal is to lengthen the time that a product can be used. By remanufacturing things like heavy equipment components, you bring them back to like new condition. In doing so, companies have increased the value we extract from the resources that went into creating those components.

What ties it all together?

At the center of the infinite loop are collection, energy recovery, and landfill. These three icons are at the heart of the circular economy as a whole. Byproducts and recycled goods are collected and processed in a way so that they can be put to further use. Energy is recovered from waste and manufacturing processes to be put to use in different operations. And whatever can’t be put to any further use, ideally goods that have had all possible value extracted from them, are finally discarded in landfills.

All of these concepts taken together have the potential to create an economy that operates closer to a closed loop than anything we’ve ever had before. Every business and each consumer has a role to play. Sometimes, though, it can be difficult to see what that role is.