When you consider your facility’s water and wastewater management, it can be tempting to stick with the status quo. But in today’s environment of dwindling resources and regulatory pressure, the “if it ain’t broke, don’t fix it” mentality might be riskier than you think.

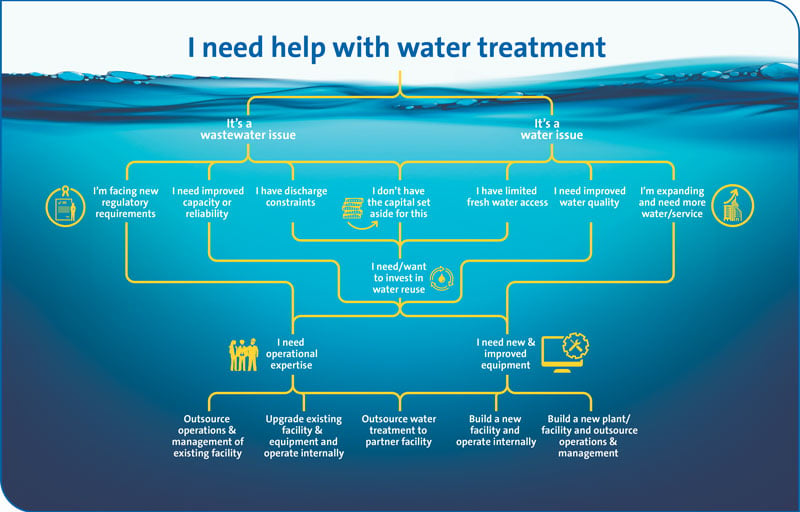

In an industry where uptime is critical, water and wastewater plant managers need guaranteed system availability, effluent quality and consistent quantities to optimize treatment and/or reuse. The following decision tree shows common challenges wastewater treatment facilities face, including new and changing environmental regulations, aging infrastructure and equipment, and operational expertise.

Environmental regulations and sustainable wastewater treatment

In recent years, wastewater treatment plants have faced a significant push to implement more sustainable practices to show environmental, social, and governance (ESG) trends for their operation. New regulatory requirements (e.g., more stringent discharge requirements), are the number one driver for plant upgrades and capital spent on system improvements.

For historical context: the 1972 Amendments to the Federal Water Pollution Control Act — commonly known as the Clean Water Act (CWA) — established the foundation for wastewater discharge control in this country. The CWA’s primary mission is to restore and maintain the chemical, physical and biological integrity of the nation’s waters. Under the CWA alone, the EPA has identified 65 pollutants and many new classes of “toxic pollutants,” of which 126 specific substances have been designated “priority” toxic pollutants.

With new and heightened regulations, traditional facilities face new challenges:

- Many wastewater treatment plants and collection facilities are now old, worn and require further improvement, repair or replacement to maintain their useful life

- The character and quantity of contaminants presenting problems today are arguably more complex than those in the past (PFOA/PFAS compounds, anyone?)

- Population growth is taxing existing wastewater treatment systems and creating a need for new plants

- Farm runoff and increasing urbanization provide additional sources of pollution not always controlled by wastewater treatment

Over 75 percent of Americans are served by centralized water reclamation, wastewater collection or treatment systems. Combined with the industrial impacts, this has brought increasing demand to ensure the protection of the environment from more than just organic pollution. EPA's National Water Program Guidance is working to adopt a numeric water quality criteria for nitrogen and phosphorus, which will expedite and help facilitate the protection of waterways.

Industrial facilities today are responsible for meeting increasingly strict regulatory requirements while ensuring the safety of their employees and surrounding communities as well as balancing reliable performance and cost.

Needing greater operational expertise, improved equipment, or both

As noted, many existing water and wastewater treatment facilities suffer from decades of dwindling investment. Old technology may no longer be cost efficient or up to current regulatory and product standards. It can be most cost effective to take a holistic or life-cycle-cost approach to a plant upgrade rather than attempt piecemeal replacements. Investing in a circular system typically results in reduced maintenance and running costs, improved process outcomes and quick ROI.

Improving your wastewater treatment facility often means some combination of upgrading internally and utilizing outside experts:

- Outsource water treatment needs entirely to partner facility with a newer, efficient, circular system

- Outsource operation and management of your existing facility to a contractor with specialized expertise, so you can concentrate on your core business.

- Upgrade your existing facility and equipment and operate internally at higher standards

- Build a new facility with modern technology and systems and operate internally

- Build a new facility and outsource operations and management to a partner with higher expertise

The three pillars of operational expertise

Operational expertise — either of in-house staff or partner specialists — in particular can be a key indicator of success. When the EPA conducted a Composite Correction Program at the Havre, Montana wastewater treatment plant, they found an increase of one operator and 24/7 operation successfully reduced the negative impact of multiple plant features previously hindering performance.

The three pillars of operational expertise:

- People — licensed, highly trained operations teams, global subject matter experts and strong leadership

- Technology — user-friendly tools that empower employees to optimize performance and sustainable systems

- Process — consistent, efficient outcomes and continuous improvement driven by rigorous standards

The three types of operation or optimization partnerships

Ensuring your wastewater treatment plant has the highest operational expertise and most up-to-date equipment keeps you ahead of the sustainability curve in addition to enabling systems and cost efficiencies and extending the life and reliability of critical assets. Building new plants or installing new equipment can be effective if you have capital allotted for such improvements, but many facilities also find solutions by contracting with outside experts.

Third-party ownership of both water and wastewater systems

Many companies specialize in providing experienced management and labor to operate both water and wastewater systems. This shifts operational responsibility and risk to the service provider while your company maintains ownership of all physical assets. These service providers specialize in water treatment and can offer higher expertise in operations, staffing and training, capital improvement projects, energy efficiency and process control techniques, while also enabling you to focus on other core competencies while accruing savings through established best practices.

Long-term O&M partnership agreements

In addition to management you can explore partnerships that include long-term agreements where the operator will pay for an upgrade or even new equipment, own, operate, and maintain it on your behalf. These types of partnerships allow for you to implement a more circular environmentally friendly process/system.

Optimization services

Optimization services can help water and wastewater treatment facilities achieve higher levels of efficiency, effectiveness and customer service among your existing staff and plant operations. Optimization consultants can elevate processes, implement innovative efficiency measures, and reduce operating expenses by up to 20 percent.

Additional benefits

Engaging in an operations or optimization partnership expert can uncover opportunities for digitalization that you might not currently be aware of. Leveraging historical data, expert experience, and technical insights of your wastewater effluent can result in significant cost and energy savings. Advanced algorithms, AI technology, remote monitoring and control can unlock value and enable maximum efficiency of plant staff.

What to look for when investing in the future:

Whether building a new wastewater treatment plant or improving existing operations, make sure you consider the services available that fit your unique needs:

- Transition plans to ensure no loss of functionality or operational interruption

- Performance guarantees

- Stellar safety records

- Real-time reporting on operational data

- Analysis of process trends and performance

- Remote monitoring of water chemical or contamination levels in accordance with regulatory standards

- Preventative maintenance system for identifying and addressing issues before they become major problems

- Updates on the accountability, reliability and value extension of your new and existing assets