“We want to hit net zero sustainability goals, but we need to incinerate these waste streams.”

If you’ve heard this before, you’re not alone. The majority of industrial businesses that aim to achieve net zero goals find that there are some waste streams that are hazardous, cannot be recycled and need to be incinerated or landfilled. There is no sustainable solution.

Or rather, there was no sustainable solution until recent years.

Along with its industrial customers, the hazardous waste industry is also constantly developing more effective and sustainable solutions for processing waste. Recycled fuels and solvents are purer, critical metal recovery from batteries is higher and pharmaceutical byproduct destruction is more thorough than ever before.

And today, for many hazardous waste streams that are destined for incineration, there is also now a more sustainable solution.

Incineration’s Rise from Disposal to Recovery

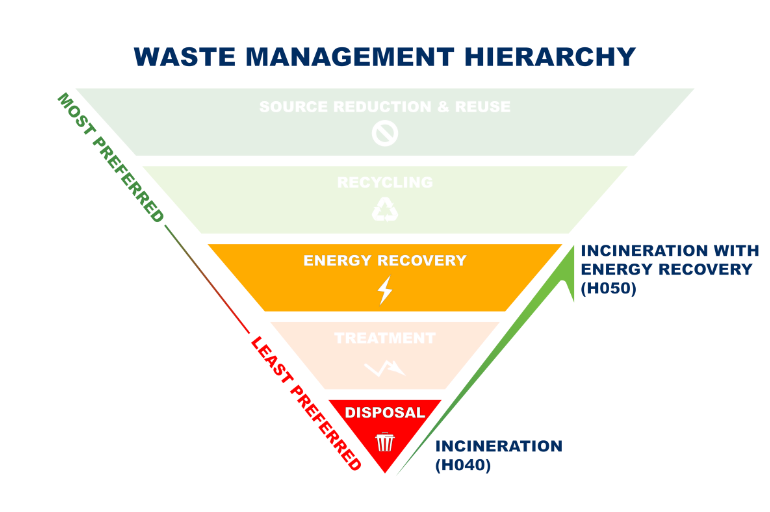

Historically, incineration and landfill were the least sustainable ways to process hazardous waste. Both of these methods were categorized as “disposal”, the lowest rung on the EPA’s waste management hierarchy.

Modern incineration facilities worldwide are increasingly incorporating waste-to-energy (WTE) technology into hazardous waste treatment operations, enabling thermal energy recovery during the combustion process.

The energy recovery system operates through the following process:

- Hazardous waste undergoes controlled incineration in accordance with regulatory parameters

- Combustion-generated thermal energy transfers to a heat recovery boiler, producing high-pressure steam

- Steam is directed through a steam turbine generator (STG) for mechanical-to-electrical energy conversion

- Generated electricity supplies on-site power requirements, reducing grid dependency and improving operational efficiency

Once the waste management method is lifted from the bottom of the waste treatment hierarchy toward the middle, this type of incineration is far more sustainable than its predecessor.

In the world of hazardous waste management, the way that a specific waste stream is handled or processed is defined by a list of EPA waste management codes. Waste streams that are incinerated with energy recovery will change from an H040 Incineration designation to an H050 Energy Recovery designation – a shift with positive ramifications down the line.

While this concept is straightforward, constructing this type of facility is not. Along with needing niche operational knowledge of how to design this process, the financial investment needed to make these upgrades is in the hundred millions, and the time investment is multiple years. As with any other CapEx-heavy emerging technology, it will be decades before this modern type of incineration facility becomes a standard.

Although there is no current equivalent energy recovery incineration facility in the U.S. for hazardous waste, the first is currently under construction in Gum Springs, Arkansas.

Three Impacts of the Incineration (H040) to Energy Recovery (H050) shift on Industrial Businesses

Industries that have historically relied on incineration to get rid of certain hazardous waste streams would benefit greatly from an energy recovery incineration facility. Here are three prime examples:

1. RCRA Waste Minimization Mandate:

Under RCRA (Resource Conservation and Recovery Act), large quantity generators must certify they have a waste minimization program in place:“Wherever feasible, the generation of hazardous waste is to be reduced or eliminated as expeditiously as possible. Waste that is nevertheless generated should be treated, stored or disposed of so as to minimize the present and future threat to human health and the environment.” – RCRA Section 1003(b)

Because the EPA considers energy recovery (H050) a form of "environmentally sound recycling" rather than just treatment, choosing H050 serves as documented proof that you are actively pursuing the waste management hierarchy. During a regulatory audit, having chosen energy recovery (H050) demonstrates a more sustainable path than incineration (H040).

2. Carbon Footprint Reduction:

As incinerators recover energy from waste burning and install decarbonized electrical sources like solar, they reduce their scope 2 energy emissions. This reduction in the total scope 1 and 2 footprint of a facility can reduce the share of scope 3 emissions reported by customers.A verifiable reduction in scope 3 indirect emissions may present potential business opportunities. When seeking capital investment, companies that can document such emission reductions (along with scopes 1 and 2) are often viewed more favorably by potential lenders, which can lead to an improved ESG risk rating. Additionally, with large corporations increasingly requiring suppliers to demonstrate emissions reduction, low-carbon suppliers may gain a competitive edge when submitting bids.

3. Sustainability Goals & Ratings Improvement:

Any company with internal sustainability goals would also benefit from this advancement in incineration. In ESG reports, claiming "Resource Recovery" rather than "Waste Disposal" reflects better on corporate environmental goals, which in turn enhances a company’s corporate social responsibility profile and brand image.For companies seeking to earn a sustainability rating from respected ESG rating agencies, this change can also improve a company’s score during the evaluation process. Rating agencies will reward companies that move waste streams up the EPA waste hierarchy. Going from H040 (Disposal) to H050 (Recovery) demonstrates an improvement in a company’s waste handling procedures.

Energy Recovery in Hazardous Waste Incineration

Energy recovery during incineration is an up-and-coming technological advancement in the United States, and it will be a huge win for sustainability.

Here’s a summary of the impacts this change will for industrial businesses:

|

Impact |

H050 (Energy Recovery) |

H040 (Incineration) |

|

EPA Hierarchy |

Recovery (More Preferred) |

Disposal (Least Preferred) |

|

ESG Claim |

Resource Recovery / Circular Economy |

Waste Destruction / Disposal |

|

Energy Impact |

Offsets fossil fuel use |

No energy benefit |

|

Reporting Status |

Shows active waste minimization |

Basic compliance |

While industry-level changes cannot happen overnight, sustainability marches ever forward in the fight to protect the environment and our shared planet. This newest innovation in hazardous waste management is a prime example of this progress.