As much as 40 percent of the United States’ food supply ends up being discarded as waste, contributing to an estimated 31 percent food loss at the retail and consumer levels. This adds up to approximately 133 billion pounds and $161 billion worth of food in 2010 — most of it ending up in our nation’s landfills. In fact, food waste makes up as much as 30 percent of the total waste stream in the U.S. and Canada, the largest contributor to the waste stream.

And it’s not just food that’s being wasted. Emptying uneaten food into landfills also consumes important resources like water. A report by the Natural Resources Defense Council illustrates how food waste ends up consuming nearly a quarter of the U.S. water supply in the form of uneaten food, or over $172 billion in wasted water.

Just how much food is going to waste?

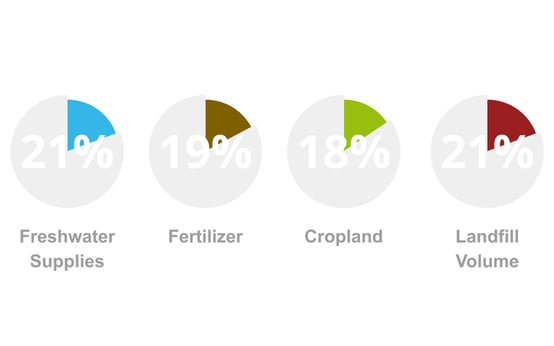

Each year, the U.S. spends over $220 billion growing, transporting, and processing almost 70 million tons of food that ends up going to waste. This uses up 21% of U.S. freshwater supplies, 19% of fertilizer, 18% of cropland, and 21% of landfill volume. All of that food waste would cover more than ¾ of California.

This comes with a heavy carbon footprint as well. When food is disposed of in a landfill, it rots and becomes a significant source of methane — a potent greenhouse gas with 21 times the global warming potential of carbon dioxide. Growing and transporting the food that goes to waste emits as much carbon pollution as 39 million passenger vehicles.

The global food system is responsible for up to one-third of all human-caused greenhouse gas emissions, making it one of the largest contributors to climate change. Yet these same statistics show the enormous potential for reducing the nation’s environmental footprint through smarter food consumption and disposal.

Thankfully, a great solution to the food waste dilemma is anaerobic digestion.

What is anaerobic digestion?

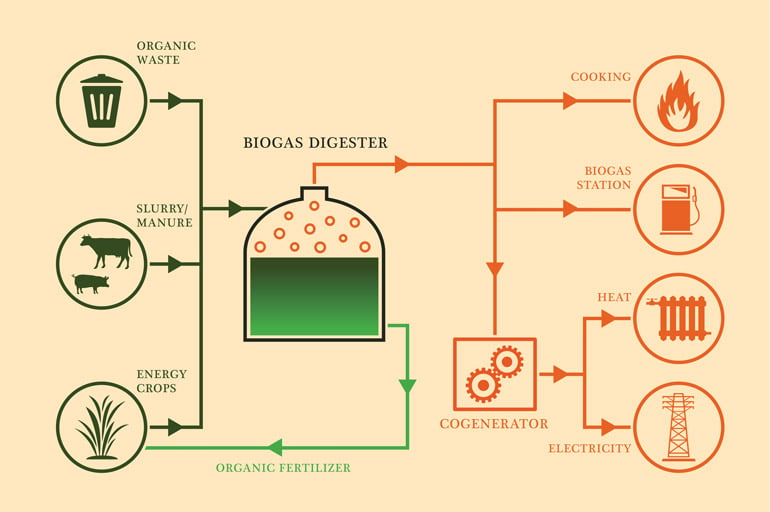

Anaerobic digestion (AD) is the natural process in which microorganisms break down organic materials. “Organic” in this case means coming from or made of plants or animals. Anaerobic digestion happens in closed spaces where there is no air or oxygen.

The following materials are generally considered “organic.” These materials can be processed in a digester:

- Animal manures

- Food scraps

- Fats, oils, and greases

- Industrial organic residuals

- Sewage sludge (biosolids)

Through the anaerobic digestion process, biogas is produced.

What is biogas?

Biogas is a renewable energy source that can be used in a variety of ways. Communities and businesses across the country use biogas to:

- Power engines, produce mechanical power, heat and/or electricity (including combined heat and power systems)

- Fuel boilers and furnaces, heating digesters and other spaces

- Run alternative-fuel vehicles

- Supply homes and business through the natural gas pipeline

How is biogas used?

How biogas is used and how efficiently it’s used depends on its quality. Biogas is often cleaned to remove carbon dioxide, water vapor, and other trace contaminants. Removing these compounds from biogas increases its energy value.

Over the past decade, the technology that goes into AD has evolved to the point that it offers a viable, economically sound alternative to disposing of food waste in landfills. This is being successfully accomplished in a growing number of communities, most notably in Canada.

How the City of Toronto uses anaerobic digestion

The City of Toronto built its second anaerobic digestion plant back in 2014 — designed to divert and revalue a broad range of acceptable materials from landfill and convert them into renewable energy and other beneficial use products at this facility.

Take the Toronto Disco Road Organics Processing Facility, for example. The operation ensures that 75,000 metric tons (55%) of the city’s residential organic waste is reused, including food scraps, soiled paper, disposable diapers, feminine hygiene products and pet waste, generated annually by the residents of Toronto.

What the process looks like

- Pre-processed organics undergo a pre-treatment system to remove non-organic materials such as plastic, glass and metal. To minimize the volume of waste sent to landfills, all non-organic materials are washed and pressed prior to disposal.

- Conversion: the remaining contaminant-free organic slurry is processed through an anaerobic digestion system where, over an approximate 15-day period, the organics are converted to biogas and digester solids.

- Reuse:

- A portion of the biogas is used to provide heating for the facility and for the functioning of the anaerobic digestion system.

- Digester solids are sent on to a composting facility in southern Ontario, where they are used to make a final Class AA compost product that is later on sold to local agricultural, commercial and horticultural markets in Ontario

- All excess liquids are treated and purified at the on-site water treatment plant before being discharged to the city's sewer

The value gained

The results of the AD process, from an environmental perspective, can be impressive:

- Creating a durable closed-loop food and organics system that replaces the end-of-life concept of waste with restoration, maximizes the use of existing resources

- Ensuring that organics are captured and revalued, which can help avoid thousands of metrics tons of carbon dioxide being release into the atmosphere

- Supplying tons of nutrient-rich digester solids for composting, an inexpensive, sustainable and natural method that reduces the need for chemical fertilizers and improves the structure and moisture holding capacity of the soil

- Improving the water sufficiency and water recovery collecting, purifying and reusing all liquid digestate, rainwater, and all other water used on-site

Because of results like these, there is enormous potential for anaerobic digestion to become a viable option for municipalities and industries that want to tackle their food waste challenge in ways that are economically and environmentally sustainable. It’s a challenge that needs to be met now.